One of the reasons for the rapidly increasing automation of labor is that industrial robots is becoming cheaper. Over the past decade, the price of robots has decreased by almost 30%, for the next 10 years, their cost is predicted to decrease by another 20-22%. Robotics not only continues to develop in large enterprises, but is also confidently moving into the field of medium and small businesses.

Main advantages:

There are a lot of robot manufacturing companies, consider some of them:

Fanuc

Number of robots installed worldwide: 400,000 (2018 data).

A Japanese company specializing in factory automation and the largest manufacturer of industrial robots in the world, judging by the number of robotic arms installed in factories around the world.

Last year, the company celebrated the production of its 500,000th industrial robot and is expanding its product range to include all new types of robots.

The range of FANUC industrial robots is very large: delta robots, painting, welding, palletizing, top-mounted robots, etc.

Application example

Flexlink, a manufacturer of automated conveyor systems, is using a FANUC M-1iA delta robot paired with an LR Mate 200iD articulated robot on a new pharmaceutical blister packaging line. The first robot aligns the position of incorrectly oriented products, as well as evaluates their quality (low-quality returns). If everything is in order, place the product on the intermediate tape and align it in front of the assembly area. The LR Mate 200iD then packs the products into the packaging. The speed of work is 60 pieces per minute.

Hanwha

Hanwha HCR-5 cobot

Hanwha is one of the largest conglomerates in South Korea. Manufacturing robots is only a small part of its business. Her collaborative robot is the first of its kind in South Korea. Cobots are a good solution for small producers. These robots have become popular because they are easier to operate than conventional industrial robots, while gaining the same benefits. In addition, they are cheaper to maintain.

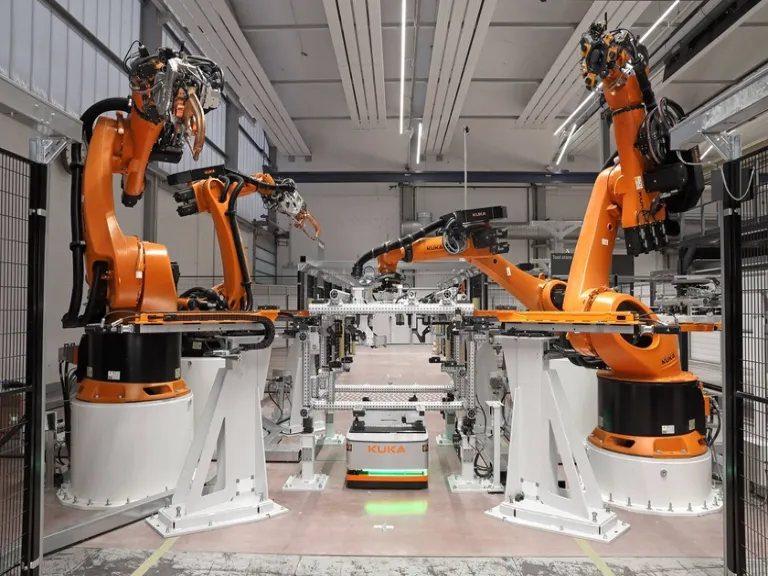

Kuka

Number of robots installed worldwide: 80,000.

KUKA offers industrial robots in a wide range, with different lifting capacities and coverage. They are used in a wide variety of industries for welding, loading, palletizing, packaging, processing, assembly and others.

Gestamp specialists produce ladder frames for Volkswagen vehicles. The Gestamp plant in Bielefeld uses a fully automatic arc welding system from KUKA Systems to ensure the highest quality, process reliability and high productivity with minimum labor requirements.

Universal robots

Number of robots installed worldwide: 20,000.

Universal Robots is a Danish manufacturer of small flexible industrial collaborative robots.

The company once proposed a lot of new things, and most importantly - the ability to use smaller and cheaper robots, which did not need to be separated from human workers. In 2008, the first UR5 appeared. In 2012, the second robot was launched - UR10. In 2015, UR3 was announced.

Universal's fantastic success is likely due in part to the fact that its robot was the first cobot in its current form - autonomous and working in collaboration with humans. But more importantly, it is a superior design that other robot manufacturers are emulating.

In 2016, Continental purchased several UR 10 robots to automate the loading and unloading of printed circuit boards and assembly of components. Transition time from one processing mode to another was cut in half compared to manual labor.

uFactory

UFactory is a Chinese startup. Released desktop robots for education and small businesses that are economical and intuitive, including uArm Swift Pro, a model for education, and xArm System, a line of cobots for manufacturing.

The xArm is available in three versions: the 5-articulated xArm 5 Lite, with a load capacity of up to 2 kg, the more flexible 6-articulated xArm6 (5 kg) and the 7-articulated xArm 7, which moves loads up to 3.5 kg.

- Today, there is a lot of hype about Search Engine Optimisation.It is really noticeable that learning to look at profound notes is known as elementary expertise

- There are a lot of things to remember before you hire a web development and web design firm. you are, then I categorical that you make the

- Lecturers at Minneapolis academic services currently voted with a new agreement that contained a provision that seniority 1Z0-996-20 Exam by your self would .

- A kid that may be house schooled is definitely a boy or girl that has an entire world of prospective buyers open to him/her. As currently being a